RIDI Group and the Railway sector

Maintainability, serviceability, impact resistance and long service life make the rail sector one of the most demanding sectors for the lighting industry. RIDI Group products come with 10-year commitment to parts availability with most products being fully serviceable.

RIDI acquired interior products from SELUX interior in 2019 such as Survivor and M150/200 that have a longstanding reputation in that sector. NORKA who also have a strong reputation in this sector provide a diverse range of products to cover most areas of rail. They also produce drivers and components to operate up to 100k hours service life and are a recognised supplier for the German railway network.

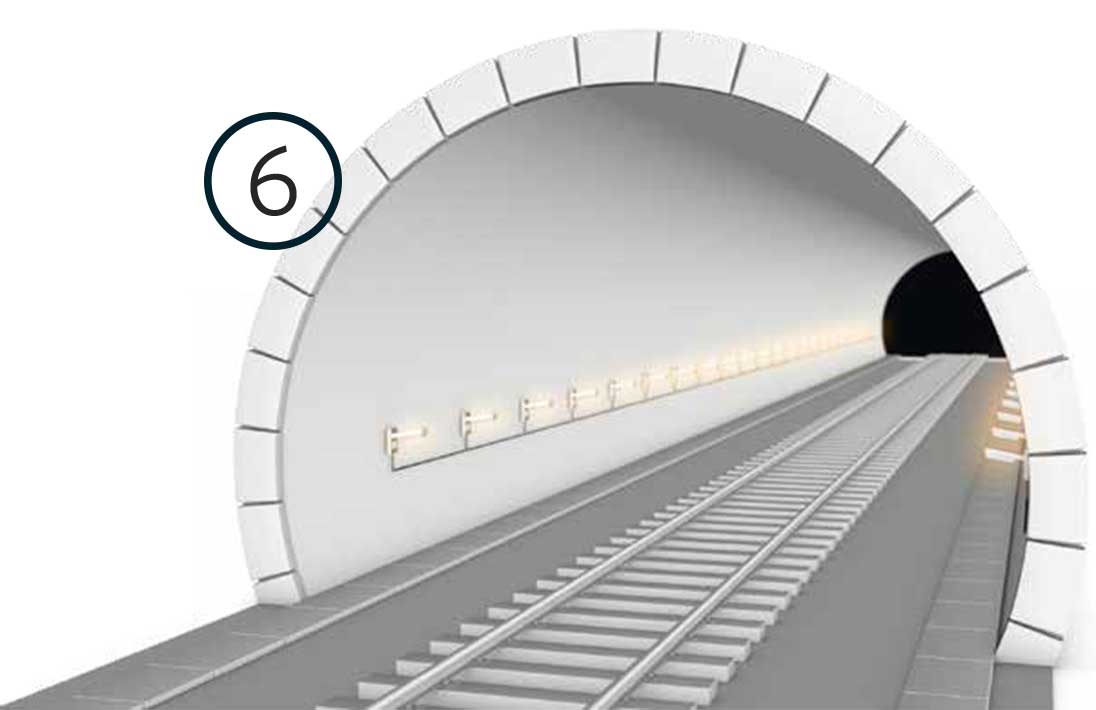

U-Bahn Station Lohring

Combination of Spectral H80-Profil and Norka Zug

1

Entrances and Concourse

Although the main public concourse spaces are not subject to the same demands of more hostile areas of the rail network, engineering quality is still essential alongside aesthetic considerations. Products in this area still need to have a high engineering integrity with high durability and long life. Also important is serviceability and access to spares.

2

Covered Platforms

RIDI Group and Norka luminaires can be used in a wide variation of ceiling systems as recessed and surface-mounted units. Within our range of products, we are also able to make bespoke products for LED retrofit replacements or for new ceiling systems.

A range of integrated lighting conduit systems exist for recessing, surface mounting or suspending. All designed to be durable, long lasting and resistant to vandalism. Most importantly, quick installation and ease of servicing are highly important for such systems.

All systems offered come with proven pedigree and have been used across many major European railway networks.

3

Open Platforms

For open railway platforms it is important to provide pole-top solutions that meet all requirements for glare free and uniform lighting. Tailored wide beam light distribution curves are required for use in public transport as well as high service life and durability.

4

Inspection Pits

NORKA have been suppliers of lighting for work and installation pits for many years. Using high-quality polymers, they are long-term resistant to embrittlement and cracking.

The materials used are resistant to heat and chemicals and always highly insulating even in case of humidity. Corrosion resistance is also a standard requirement across all the range.

NORKA work pit luminaires meet all requirements made forthem to be extremely reliable and low-maintenance, even under difficult operating conditions such as:

- Protected against dust and water jets

- Dirt repellent

- Resistant to impact and corrosion

-

Resistant to acid, lye and fuel

-

Oil-resistant

-

Resistant to pressurised water

5

Underpasses

The luminaires installed in these areas are sometimes at risk of deliberate or negligent destruction. The problem is exacerbated by the fact that many of these infrastructure passages with have low ceiling heights and are exceptionally vulnerable. As a result, the impact rating demands are probably at their highest. Solutions exist for recessing, surface mounting and even cornice mounting.

6

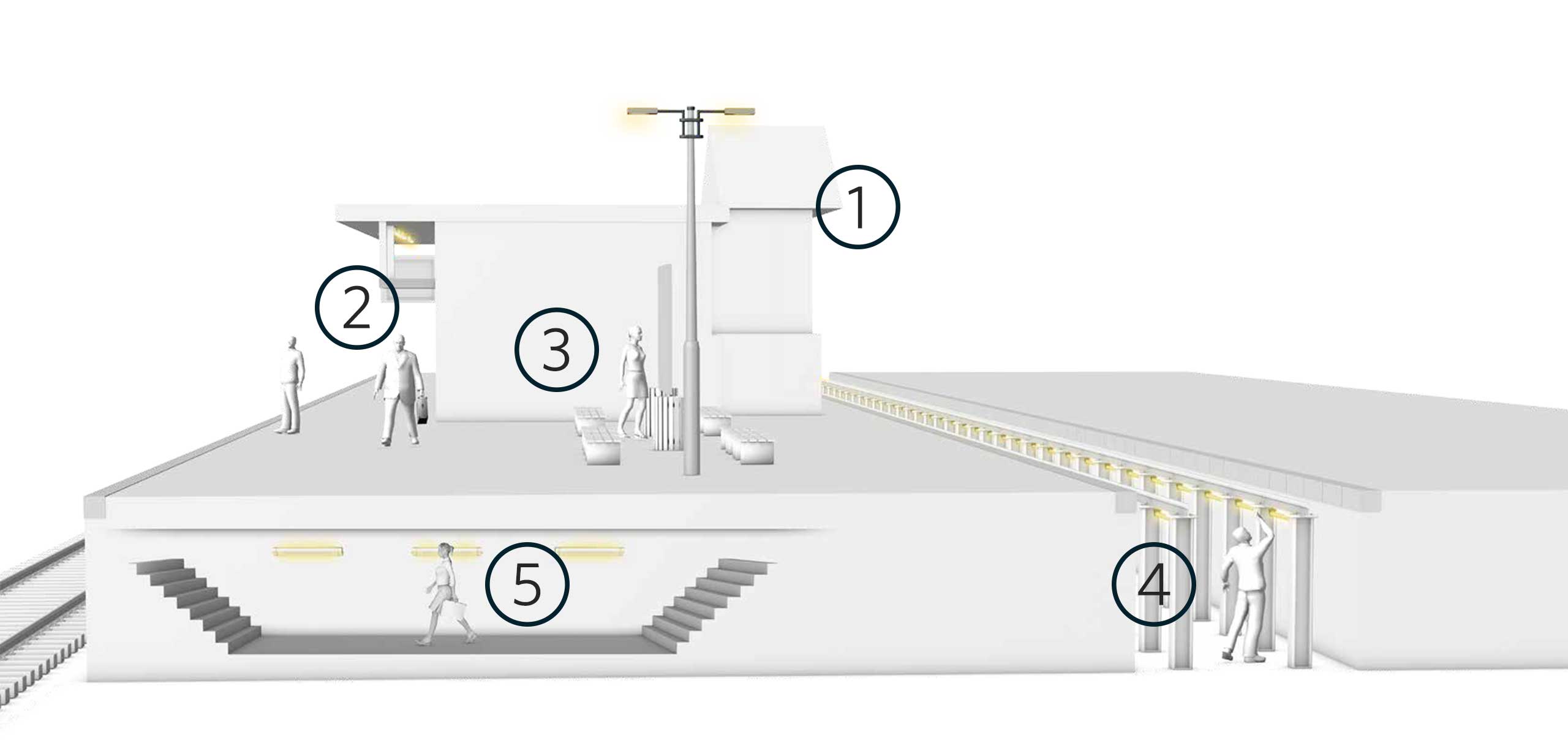

Tunnels & Safety Lighting

For railway tunnels, luminaires face different challenges. For example, a fully assembled luminaire with external connection will ensure easy installation and short installation times. Crucial when working out of hours.

Luminaires should have ideally adapted light distribution, extreme wide beam, for illuminating escape and emergency routes in tunnel systems. They are required to meet the requirements for emergency luminaires in line with EN 1838, EN 60598-2-22 (VDE 0711-2-22) and tunnel safety lighting in line with the Railway Directive 954.9107.

The wall surface-mounted luminaires supplied by Norka have corrosion-resistant IP65 weather-proof housings made from polymer together with stainless-steel wall brackets. Combine this with age resistant, non-deforming gaskets, this makes them highly suitable for the high safety standards in tunnels where they endure extreme strain.