Circular economy in the Rail sector. Q&A with Jon Estell

Who better to speak to about RIDI Lighting’s Rail sector products than Jon Estell?

Jon previously worked as part of the Rail project design team for Selux Lighting and gained years of valuable experience working in partnership with London Underground, Network Rail and the DLR.

He now works for RIDI Group UK as Head of Spectral Lighting UK:

He is interviewed by Jo Harding of Hardingconsult.

Q: ‘Jon, How and when did you first get involved in lighting for the rail sector?

After the horror of the Kings Cross fire in the late 80’s and the Fennell Enquiry that followed, new legislation was enacted in Section 12 of the Fire Precaution Act 1971, namely The Fire Precautions (Sub-Surface Railway Stations) Regulations 1989. This outlined stringent rules that were put in place to eliminate combustible materials in any products used below ground. Molten plastic igniting rubbish was cited as one of the reasons for the fire. Quite a challenge for lighting manufacturers as plastic optics were the basis for many products at the time. A list of approved lighting products that could be specified for sub-surface stations was published. In order to get on the list it required manufacturers to perform exhaustive tests and go through a protracted certification process. I was part of a team from Selux who I worked for at the time, that developed and sought accreditation for the products. Many of the products we presented had been developed for the German Rail network, Deutsche Bahn (DB) and there was a very close synergy between the UK and German network. I remember many presentations took place at Metronet’s London offices part of London Transport. We did a lot of consultation work and were very proud when we got on the list of approved lighting products.

Q. Can you tell us about your product design background?

I went to Ravensbourne college of Design and studied Three Dimensional Product Design. In my final year I designed an ergonomic cab for a tram car of the future. I also won a competition to work for a lighting company and it was the seed that started my two and a half decade career in the lighting industry thus far. I still have close links with the college, lecturing there and have run lighting projects with the second year students.

Q: What are the challenges of developing lighting products for this sector?

Sustainability and maintainability are the two key headlines for the design of modern and future rail lighting products. In future we must consider the impact of throwing away old lighting products and replacing with new. Is that necessary? Can we reuse the existing housings, for example, that could well last for decades as opposed to removing and disposing of them? If we have long life products how can we effectively and easily clean them? The impact on lighting products when a train goes through a platform at speed is immense. Brake dust from trains can coat the surfaces and corrode finishes.

Q: What changes and trends have you seen in the Rail Sector over the last 10 years?

The big change was the move from traditional lamp sources such as fluorescent and halide to the wholesale adoption of LED over a decade ago. LEDs have allowed us to integrate lighting into architectural features. They have massively reduced electrical load and heat.

Q: What do RIDI Group/ Spectral bring to the table?

RIDI Group acquired the Selux interior and transport product ranges in a move to improve existing iconic products. Some are currently lighting much of the lines on London Underground stations such as the Survivor on the Central Line and The M125 on overground stations such as Blackfriars. RIDI Group have re-engineered the products which has seen major improvements in energy efficiency as well as reducing the component count and buildability. Our product design process has allowed us to integrate the products into our own manufacturing plants and we use local suppliers for key components. The main factory where the products are now made is run purely on Biomass renewable technology.

Q What’s the product you enjoy working with the most?

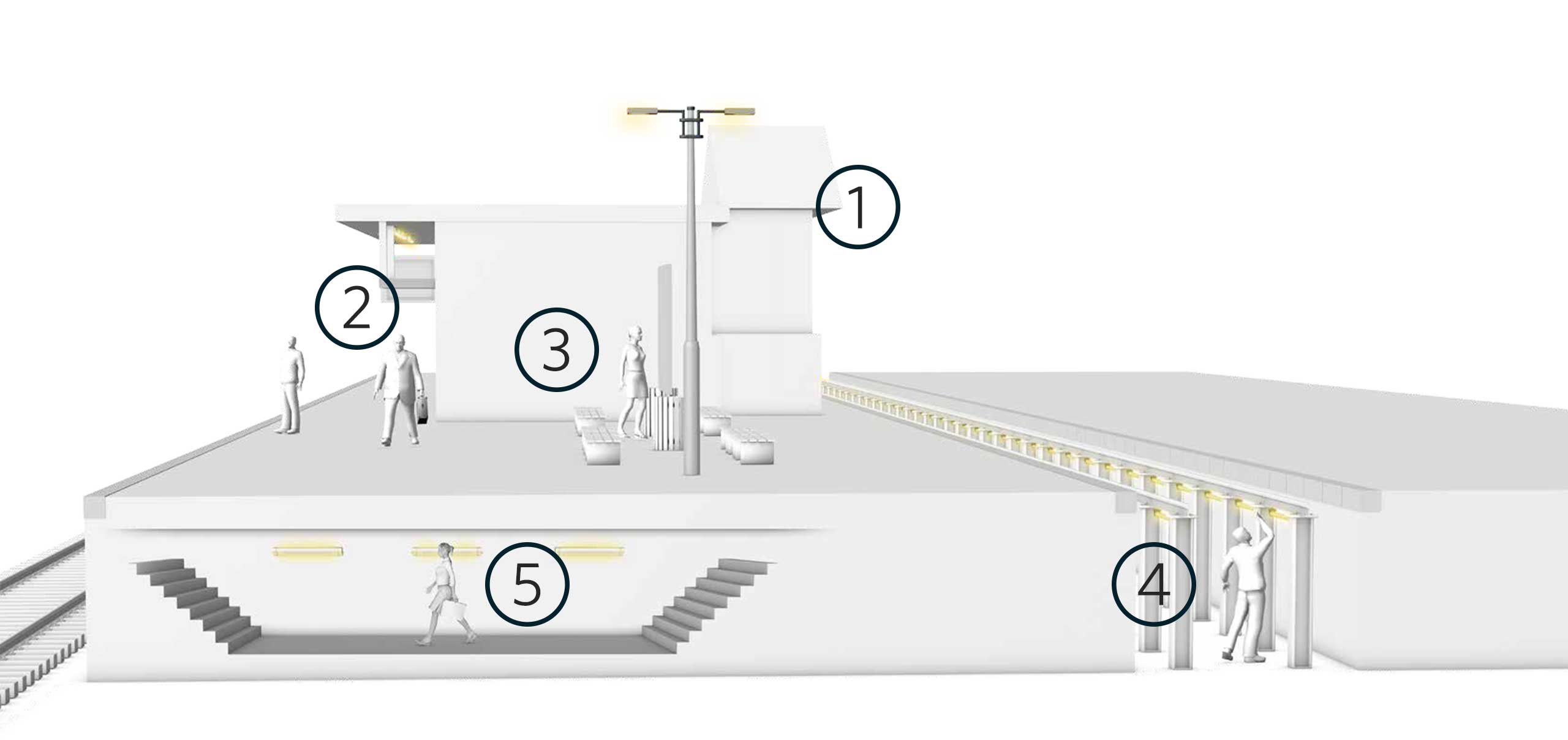

For the transport sector, the sheer scope and adaptability of the Survivor and M Series ranges makes them highly desirable. The integration of PA speakers, cameras and the ability to integrate cabling trunking within the bodies makes them an invaluable tool for station platform and concourse designs.

Q: Outside of lighting, what are your passions?’

Cars and pedal bikes are my passion. I love their design and engineering. I ride road and mountain bikes for pleasure and this year have set up VeloLight with a good friend of mine who I met when I first started in the lighting industry (he happens to also be a product designer). We aim to attract like-minded riders from the lighting industry to raise money for a local charity called Charlies Gift who provide grants of money to children who face challenges in life because of health issues, special needs and disability, bereavement or poverty.

If you have any questions about RIDI’s Rail sector projects then please contact Jon Estell at Jon.Estell@ridi.co.uk

Ridi Lighting Ltd is proud to announce the acquisition of Lightworks with effect from 1st September 2023.

Richard Holt announced as the new Managing Director of the company.

See our new personal circadian lighting luminaire at Light 22

Spectral Lighting to launch exciting new concept in Circadian Lighting at Light 22

Responsible Light Video Blog Episode 5 : Well Light

Responsible Light Episode 4 – Design Standards

Responsible Light Video Series Episode 3: Smart Lighting

Responsible Light video series Episode 2 : Sustainability

Mike Attard is interviewed by John Bullock of the Light Review

How we at RIDI are taking our lighting responsibility seriously.

Circular economy in the Rail sector. Q&A with Jon Estell